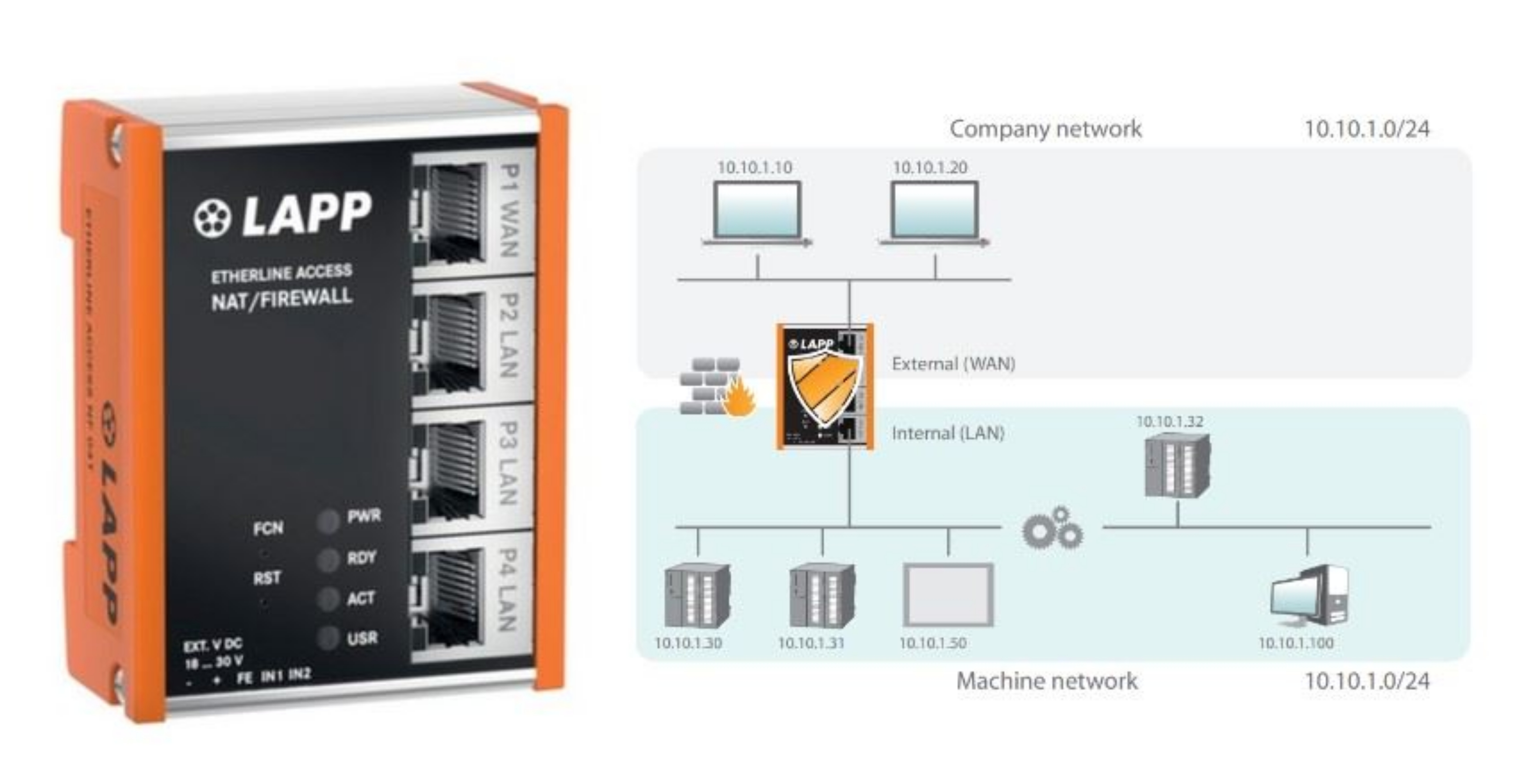

The new ETHERLINE ACCESS from LAPP

The new NAT / Firewall from LAPP solves three key headaches for Machine Builders

The new ETHERLINE ACCESS from LAPP

The new NAT / Firewall from LAPP solves three key headaches for Machine Builders

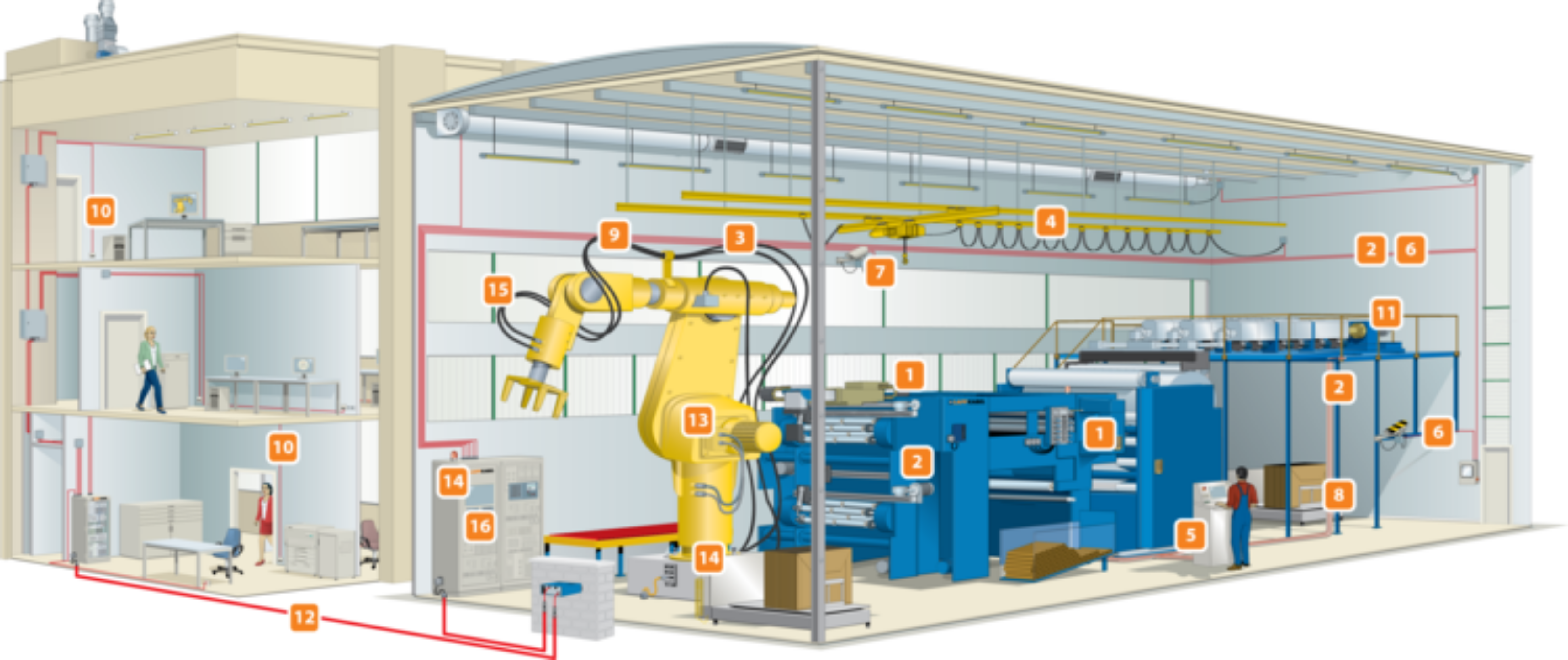

ROCKWELL & SIEMENS Compatible servo assemblies, European CEE connectors, innovative Lever Terminals, smart electronic devices, rugged fanless Industrial PC's and modular switchboards for mid to large

Looking to simplify your connectivity, yet have a flexible and cost effective way of having remote connectivity into your plant and application? LAPP in collaboration with TOSIBOX would like to show you how easy this is to create a secure remote connection to your process automation plant for seamless access. No more worries around being offline and concerns for driving to the plant. Mark Dilchert from TOSIBOX Australia will be personally guiding you through how simple these units are to setup and how you today can create your own secure VPN networks.

LAPP is playing a critical role in future-proofing automation capabilities by providing an array of data transmission products that are designed not just for today, but for ever-evolving communications needs.

This video provides an example of how to convert Modbus RTU to PROFINET protocol with Moxa’s MGate 5103 Series. Moxa MGate protocol gateways support an easy-to-use web console that guides users to configure the protocol conversion step by step, making the configuration process hassle-free.

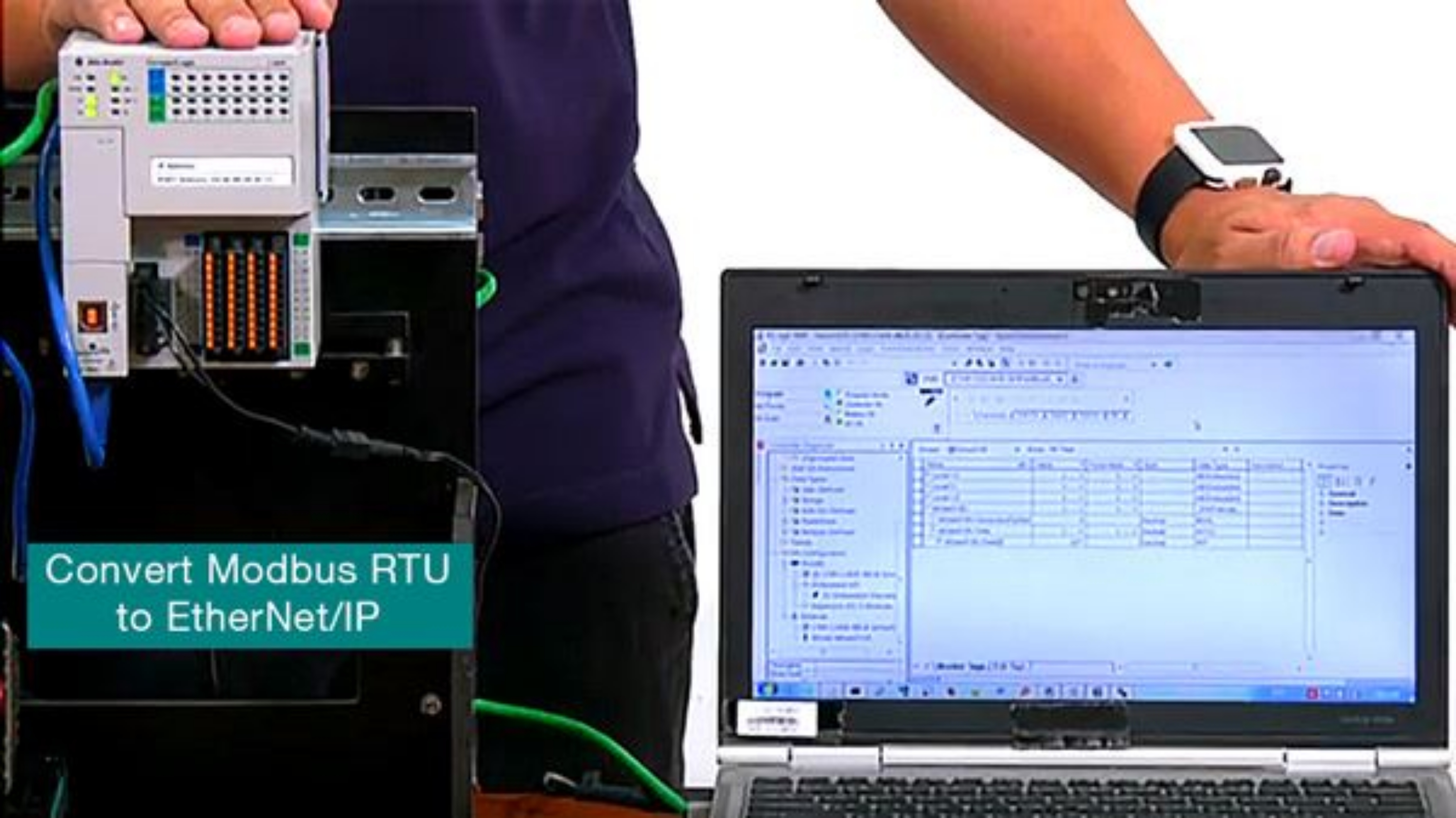

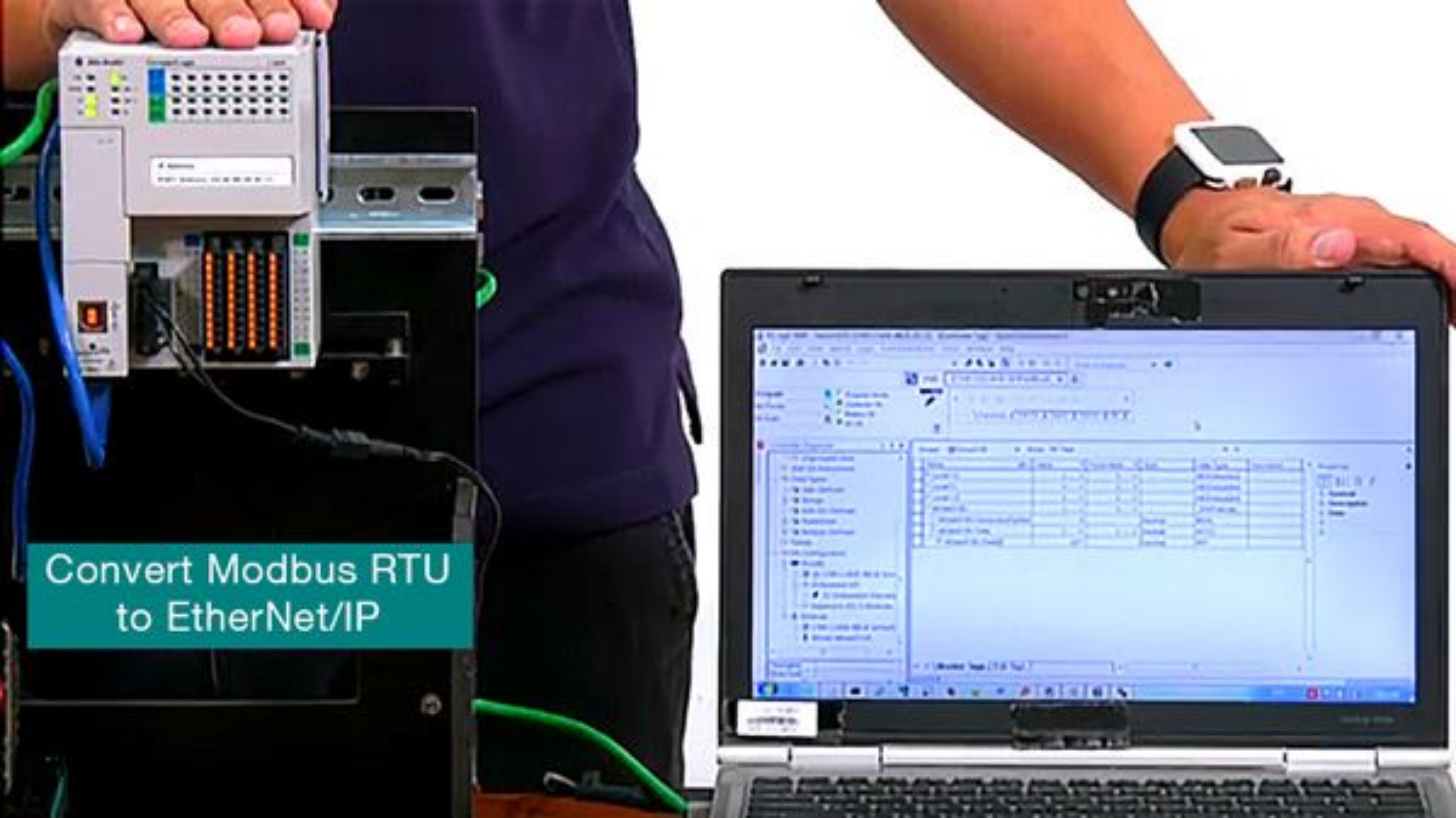

This video provides an example of how to convert Modbus RTU to EtherNet/IP protocol with Moxa’s MGate 5105-MB-EIP Series. Moxa MGate protocol gateways support an easy-to-use web console that guides users to configure the protocol conversion step by step, making the configuration process hassle-free.

ECS are very pleased to announce that we are an authorised distributor for TOSIBOX® in New Zealand. TOSIBOX® have created a new standard for secure connectivity, remote maintenance and network management. The award-winning TOSIBOX® products are manufactured in Finland and used worldwide.

Recently, there has been a rise in the sophistication of cyber attacks, which has prompted everyone from IT to OT personnel to produce solutions that enhance industrial cybersecurity.

While companies are tapping into the opportunities that the Industrial Internet of Things (IIoT) has to offer, digitalization has become a key initiative for industries. Digitalization has allowed the industrial control system (ICS) landscape to develop quickly in recent years. Originally, ICS networks were physically isolated and almost immune to cyberattacks.

For control engineers, their primary goal is to ensure that they have system availability, but they often do this without focusing on the network status. This gap is becoming problematic because even though the internet of things is helping to connect more and more devices, it is unfortunately increasing network complexity and introducing new security risks. What if control engineers had clear visibility of the network status and could quickly identify the root cause of network downtime?