Wherever food and beverage are involved, hygiene is at the top of the agenda.

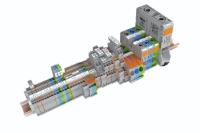

Cables, connectors and cable glands play a crucial role in Hygienic Design, which is so important to food and beverage processing facilities.

In the food and beverage industry, any stoppages not only lead to profit losses, but also high costs from waste disposal and recommencing production.

To prevent this double loss and keep production flowing smoothly and hygienically, it’s important to consider five key factors:

1. The three hygiene zones. Will the cable or component be used in the non-product zone, the splash zone, or the product zone? Specialised products are needed for areas where constant contact with foodstuffs occurs.

2. Resistance to cleaning agents. Chemicals used in cleaning processes can be particularly strong, and if the wrong materials are used, there is a danger that some system parts will lose their protection rating.

3. The individual application counts. It’s important to consider each facility as unique in order to specify the ideal cable type. For example, in applications with large temperature fluctuations, condensation can form and collect in the protective conduit – and this is unhygienic in the long term. In this case, the better option is to use an openly installed and highly durable cable in connection with an appropriate cable gland which follows the principles of hygienic design.

4. No germs allowed. Germs and bacteria can easily build in corners or edges, so smooth, curved designs can often help prevent this unhygienic build-up. Products like Lapp’s SKINTOP® HYGIENIC provide no surfaces for contaminants to attack. All seals are fixed tightly to the cable and connection point with no gaps. Instead of an O-ring, it has a radial moulded seal above the connection thread, a sealing ring below the domed cap nut and a specially formed conduit sealing ring on the cable. It has smooth surfaces and no edges, meaning that remaining food cannot settle there and can easily be washed off.

5. Signal colour blue protects against losses. The food and beverage sectors require blue products in many instances, because if a piece of plastic were to somehow fall into the food, it would be easier detect it this way, because in nature there are no materials with such an intense blue colour. This is also the case for the cable ties, which Lapp provides especially for the food industry. They are blue and also contain an admixture of metal. This means that a missing cable tie can be retrieved very easily using a metal detector or an X-ray unit.

Special cabling solutions for the food and beverage industry are now already helping to increase productivity, safety and quality in the sector. The Lapp Group's newly developed and newly qualified portfolio for the food and beverage industry is being further expanded according to customer requirements.