ÖLFLEX® Drag Chain Cables

FLEXIBLE SOLUTIONS FOR MODERN MANUFACTURING

Specifically designed for constant moving applications, ideal for the most modern automated manufacturing systems for both indoors and out.

These cables are engineered to meet the highest service life requirements, ensuring reliability and longevity in the most demanding industrial environments.

Our Key New Zealand Drag Chain Cable Range

ÖLFLEX® FD Classic 810 & 810 CY

Featuring a copper braid which is also beneficial where EMC protection is required.

- PVC robotics cable

- Highly flexible

- Suitable for continuously moving applications, in power chains or machine assembly lines

- Cost effective for medium duty applications

ÖLFLEX® FD CLASSIC 810 P & 810 CP

Featuring screened braiding which is used where EMC protection is required and a PUR outer sheath for increased wear and tear resistance.

- Polyurethane (PUR) based version of the highly flexible ÖLFLEX® FD Classic 810 robotics cable

- It reduces the amount of space required in power chains

- Still offers minimum bending radius of 7.5mm x cable diameter

- PUR sheath offer greater protection for abrasion, chemicals & has high oil-resistance

ÖLFLEX® FD 855 P & FD 855 CP

Featuring screened braiding which is used where EMC protection is required and a PUR outer sheath for increased wear and tear resistance as well as having the expanded temperature range.

- This cable has been designed to resist extreme stresses

- The materials used are halogen-free and environment-friendly

- It can be used in an expanded temperature range

- The unscreened version allows a minimum bending radius of 5 x cable diameter

ÖLFLEX® FD ROBUST & FD ROBUST C

Featuring screened braiding which is used where EMC protection is required and a TPE outer sheath for increased wear and tear resistance as well as having the expanded temperature range and the improved chemical resistance properties that the TPE sheath offers.

- A control cable for high flexible use and for robust mechanical use

- Has an increased resistance against acids, caustic solutions and certain vegetable, animal and mineral oils

- It is ideally suited for use in agricultural, food, beverage and pharmaceutical industries

- Increase temperature range -40℃ + 105℃

- Has approvals for the North American and Canadian market

ÖLFLEX® FD 90

High-flexible sheathed cables designed for the European, North American and Canadian market.

- Suitable for flexible use and fixed installation, for medium mechanical load conditions

- The PVC sheath has increased oil resistance

ÖLFLEX® FD 90 CY

Specially designed for power circuits of servomotors driven by frequency drives.

This cable can substitute screened multi-core cables where space is an issue or where minimum bending radius needs to be improved.

- High-flexible screened single core for EMC applications.

- Has the required approvals for all international projects - European, North American and Canadian market

- Suitable for flexible use and fixed installation, for medium mechanical load conditions

- The PVC sheath has increased oil resistance

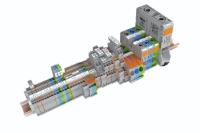

ÖLFLEX® ROBOT 900 P & 900 DP

Featuring Screened Braiding for EMC protection when required.

- This cable handles the transmission of control and monitoring signals as well as power supply to the installation

- Suitable for any installation where combined torsion and bending stresses occur like feeding signals or power to robot heads.

- Suitable for connecting handling tools to welding robots and for connection to rotating or tilting tables

_5000.jpeg)