MTS have expanded their high-performance R series 5 transducer range to have even higher performance and more output protocols.

MTS R series 5 magnetostrictive position transducers are Industry 4.0 featured with CE and EAC approval. Designed and manufactured to offer extremely precise and reliable position feedback measurement for motion control and automation. They are rugged non-contact devices that function in extreme temperatures, at great pressures under continual shock and vibration. Industries include Automotive, Aerospace, Medical, Renewable energy production, Timber harvest and process, manufacturing and logistics, mining, steel manufacturing and mobile agricultural equipment

Series 5 benefits compared to standard R Series

- Web connectivity with sensor via Tempolink Smart Assistant for transducer configuration and diagnostics

- Increased mechanical shock rating 100G to 150G

- Increased vibration rating 15G to 30G

- Increased maximum operating temperature 75 to 85 degrees C

- Increased IP rating IP65 to IP67

- Increased power supply voltage range 12Vdc to 30Vdc

- Increased maximum pressure 690 to 700 Bar [ rod style RH5 ]

- Reduced power consumption

- Cost effective

Features

- Minimum resolution of 0.1 µm with up to 100 µs cycle time, stroke length dependant

- Position, velocity and acceleration measurements for up to 30 magnets, model dependant

- Field adjustments and diagnostics using the new TempoLink smart assistant through power supply

Outputs Include

- Analog

- SSI

- EtherCAT

- Ethernet I/P

- Profinet

- Powerlink

MEASURING TECHNOLOGY

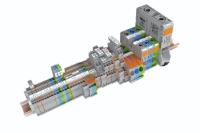

The absolute, linear position sensors provided by MTS Sensors rely on the company’s proprietary Temposonics® magnetostrictive technology, which can determine position with a high level of precision and robustness. Each Temposonics® position sensor consists of a ferromagnetic waveguide, a position magnet, a strain pulse converter and supporting electronics. The magnet, connected to the object in motion in the ap plication, generates a magnetic field at its location on the waveguide. A short current pulse is applied to the waveguide. This creates a momentary radial magnetic field and torsional strain on the waveguide.

The momentary interaction of the magnetic fields releases a torsional strain pulse that propagates the length of the waveguide. When the ultrasonic wave reaches the end of the waveguide it is converted into an electrical signal. Since the speed of the ultrasonic wave in the waveguide is precisely known, the time required to receive the return signal can be converted into a linear position measurement with both high accuracy and repeatability.

R-SERIES V EtherCAT®

Temposonics® R-Series V brings very powerful sensor performance to meet the many demands of your application. The R-Series V is the long-term solution for harsh environments that have high levels of shock and vibration. The sensor supports the EtherCAT® specifications including distributed clock. The mechanism of distributed clocks enables a synchronized communication with a minimum cycle time as fast as 100 µs. For time-critical applications R-Series V with extrapolation allows synchronized controller communication for any stroke length of the sensor.

In addition to position and velocity, the acceleration for up to 30 magnets can also be reported. Temposonics® R-Series V sensors are available with internal linearization which offers improved linearity for overall higher accuracy of the position measurement values. In addition to the measured position value via the EtherCAT® protocol further data about the current sensor status, such like the total distance travelled, the internal temperature and the total operating hours, can be utilized for diagnostic purposes. With many outstanding features the R-Series V sensors are fit for a very broad range of applications.

TempoLink - YOUR SMART ASSISTANT

The TempoLink Smart Assistant is an accessory for the R-Series V family of sensors that supports setup and diagnostics. Depending on the sensor protocol it enables the adjustment of parameters like measurement direction, resolution, and filter settings. For diagnostics and analysis of operational data the R-Series V sensors continuously track values such as total distance travelled by the position magnet, internal temperature of the sensor and the quality of the position signal.

This additional information can be read out via TempoLink smart assistant even while the sensor remains operational in the application.TempoLink smart assistant is connected to the sensor via the power connection, which now adds bidirectional communication for setup and diagnostics. The TempoLink smart assistant is operated using a graphical user-interface that will be displayed on your smartphone, tablet, laptop, or PC. Just connect your Wi-Fi-enabled device to TempoLink Wi-Fi access point and go to the website URL for the user-interface.